Intercooler of the EA288

Repair solutions from VEMO

The EA288 engine from Volkswagen uses a water-cooled charge air cooler. In this article, we explain how it works, what problems can occur and how VEMO can help with practical repair solutions.

EA288 engine from VW: Special feature water-cooled intercooler

The EA288 engine has a water-cooled intercooler, which optimises the efficiency and performance of the engine. By integrating a water-cooled intake manifold, the temperature of the intake air is effectively regulated, resulting in improved combustion and lower emissions.

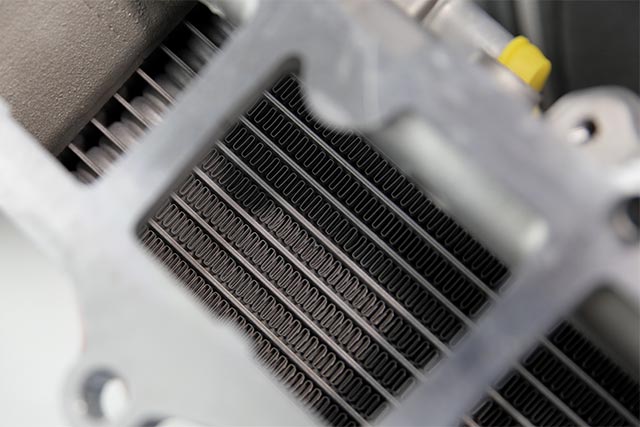

Intercooler / heat exchanger: How it works

The main task of an intercooler, also known as a heat exchanger, is to reduce the temperature of the compressed air generated by the turbocharger before it enters the engine’s combustion chamber. The operation of an intercooler is based on the principle of heat exchange. When the air compressed by the turbocharger flows into the intercooler, it is channelled through a network of cooling fins. As the hot compressed air flows through the intercooler, it transfers heat to the cooling fins, which cools the air. Overall, the intercooler plays a crucial role in optimising the performance and efficiency of a combustion engine by lowering the temperature of the intake air and thus improving engine performance.

Problem with the EA288 engine – Defect in the charge air cooler

The charge air cooler of the EA288 engine is susceptible to defects. Thermal stress can cause leaks, which can lead to a loss of cooling water and damage the engine in the long term. A typical sign of a fault in the EA288 charge air cooler is a gradual loss of cooling water, accompanied by an oil-water emulsion on the fourth cylinder. Without repair, the leaking cooling water can lead to engine damage and expensive repairs.

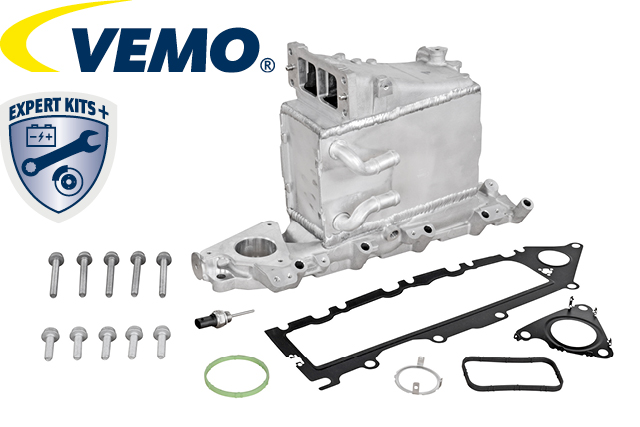

Repair solution: VEMO ExpertKits for EA288 intercoolers

VEMO offers a complete repair solution for defective EA288 intercoolers. Our ExpertKits contain high-quality spare parts and all the necessary components for a reliable repair, including gaskets, screws and a new intake air temperature sensor.

Tip: Bleeding the cooling circuits

An important tip when repairing the EA288 engine: It is essential to ensure correct bleeding in accordance with the manufacturer’s specifications. The engine has a complex thermal management system with several cooling circuits. If these are not bled correctly, air bubbles in the system can lead to serious engine damage. It is therefore important to carry out the special bleeding test programme, which takes approx. 15 to 20 minutes.